Feeding our food before it gets on our plate

Like most other industries, fish farming businessmen are turning to technology more and more by the day. The use of artificial intelligence has expanded across departments, and recently it has found substantial cost-reducing solutions.

Salmon – one of the priciest fish in the world – is also one of the most consumed worldwide as its preferred for its taste both in cooked meals and in raw recipes. We all love to eat salmon, but before it makes its way to our plates, it needs to eat and grow as well. And that’s exactly what fish farmers are currently investing in – the food intake of salmon fish.

Considering the industry currently grows over 100 million tonnes of fish per year, scientists have made use of automation and lasers to find solutions in the perfect amount of food to be provided to them.

The country of Norway, which produces about three million salmon per year, has concluded that the fish make less noise once their bellies are full.

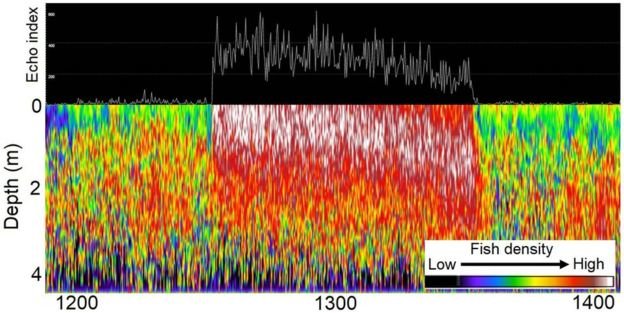

They came to this conclusion through the use of a new hydro-acoustic system which they use at their fish farms named Lingalaks. The system accepts the chewing sound signals while the fish are being fed in clusters, after which they eventually swim off and the noise lessens.

The CEO, Erlend Haugarvoll expects to make use of this information, in addition, to save up on fish food costs. A good amount of the food currently goes to waste, and by using laser technology he believes it could reduce expenditures by roughly 5%. This would equal to $900,000 – $1.3m of savings for the fish farms.

Artificial Intelligence Takeover

The hydro-acoustic system has been developed by CageEye, a technology firm whose executive Bendik Sovergjarto is proud of. He explains the system does not count for the leftover fish pellets in the water.

That would lead to inaccurate results, as one can’t be certain whether that quantity appropriately represents if the fish have been fed or if the water currents have changed their locations.

Subsequently, they’d be looking in the wrong place. Instead, the fish farms will use the chewing sounds while they are being fed to estimate the appropriate food amount. Mr. Sovegjarto claims this new system could save the farms over $1bn a year.

One of the goals is to develop entirely automated feeding systems and have humans involved in roles of overseeing processes only. Other data found has to deal with water oxygen levels, water temperature, and other salmon feeding patterns.

They have been monitored by the Institute of Marine Research in Bergen, and the system’s technology has been developed in accordance with the findings by Ole Folkedal. There is variety in how much to feed fish in any given day, and the data is being carefully examined to determine the influencing factors.

Further use of artificial intelligence has been used in an industry as lucrative as salmon farming. Aquabyte, which is a new startup, has raised about $3.5m which makes better use of surveillance data of previous recordings.

The most modern fish farms insert small cameras in the pens which record the fish while being fed, and attempt to determine how much to feed them using images and computer vision algorithms.

Through this system, computers visually monitor the group of fish being fed, and particularly also look out for potential visitors to the fish – lice. This parasitic sea louse has been problematic to fish farmers as long as they’ve been produced as if attached to the fish it could cause fatal consequences.

In addition, it turns the salmon into a damaged good and can be no longer sold, as it becomes inedible, Aquabyte CEO, Mr. Shang, is looking forward to improvements in the industry due to technology, as they will hopefully be able to detect the lice and remove it automatically. This helps decrease the number of inedible salmon, and subsequently improve loss of sales.

Mr. Shang seems to not be thinking big enough in terms of the future of technology, as the removal of the lice is completely achievable in the near future too. This is where lasers come to use, as Stingray has developed a self-guided tool which fires laser beams to destroy the lice in salmon.

This development is perfect in the case of salmon, who has a mirror-like skin reflecting the laser and remaining unharmed. The only hit goes to the sea lice, who coagulates in milliseconds and detaches from the salmon.

Norway certainly makes a fortune off of this wealthy sector, estimated at roughly $6.4 bn a year. Furthermore, a 9% growth of farmed salmon fish is expected to be seen in production. The biggest company in the country, Salmar, owns a humongous installation about 120 yards, with Ocean Farm 1 alone having a capacity of 1.5 million fish.

Other technologies include visual monitoring of salmon being fed in cages. Hemang Rishi of Observe Technologies has been strategically developing similar technology in Chile, which is the second largest salmon market in the world. Norway, as it has been pointed out above, takes the 1st place.

Moreover, Atlantic Sapphire based in Florida has been working towards constructing a huge salmon farm. But instead of having it in water, they are doing it on land. That is being achieved through large tanks, which swirl the water automatically to maintain the illusion of the salmon being at sea.

Although it could be foreseen that automated systems will take over many industries in the future, law regulations in Norway require humans remain involved, at least for now. It requires routine checks for illnesses and mortalities among the fish, to ensure the high quality it currently possesses.